Axle Weigh Pad Calibration

At MWS we have two 12.5 tonne UKAS accredited calibration rigs designed to test and calibrate vehicle weighing pads using reference load cells, our rigs are tested and certificated to ISO 17025 allowing us to carry out UKAS calibrations.

UKAS Calibration of Portable Weigh Pads

As of 2026, Micro Weighing Solutions can offer full UKAS traceability for axle weigh pad calibrations. In 2025, MWS was audited by UKAS on our calibration procedure/documentation, and we have now been accredited.

Our schedule of accreditation specifically documents and clearly states that we are within scope to carry out UKAS calibration of weigh pads using force calibration methods up to 12.5t (12,500kg per pad).

Therefore our certification is fully compliant with requirements outlined by the VCA and DVSA.

The VCA do not “approve” any UKAS service, please be wary of companies stating their process has been approved by the VCA, it hasn’t.

Due to the design and physical size of a weigh pad it is impossible to take them up to a high enough capacity using block weights (mass). It is only possible to safely load weigh pads to around 1 or 2T using 1000kg cast iron test weights, even then you cannot take the pads up to a reasonable load that the axle pads should be tested to.

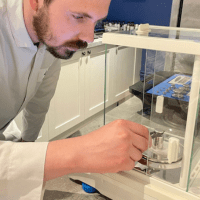

MWS has invested in a purpose built test rig to enable us to safely load to 12,500kg and perform accurate calibrations to ISO 9001 and UKAS ISO 17025 standards.

Contact us to find out our rates for accurate and safe calibration of your vehicle weighing pads.

Axle Weighing Pad Calibration

Axle weighing pads are the most accurate way of determining axle weights on a truck. They are usually used when there is a need for more accuracy than what is possible with a standard scale. The calibration process of these pads is crucial as it ensures that they provide accurate readings every time.

The axle weighing pads are also known as weight distribution bars, and are used to evenly distribute the weight on an axle. These bars are placed in front or behind the wheels, depending on whether the client wants to measure the front or rear axle weights respectively. The process of calibrating these bars includes setting the pad height and ensuring that it is level with the ground, and then using a scale to measure its weight.

Benefits of Axle Weighing Pad Calibration

Axle weighing pads are used to even out the axle weight of trucks and trailers. These pads are fitted onto the axle and weigh the axle’s weight, tires, and axles. Calibration is done by using a load cell that measures its force when loaded with a standard weight. The result is then calculated using a formula.

The benefits of Axle Weighing Pad Calibration include:

- Ensures truckers pay for their fair share in highway taxes

- Ensures trucks do not exceed their maximum allowable weight

- Prevents accidents due to overloaded vehicles

Axle weighing pads are a vital component in the trucking industry. Trucks carry a heavy load which can be taxing on the axles, and axle weighing pads help distribute the weight.

How to Perform an Axle Weighing Pad Calibration Check

Axle weighing pads are devices used to even out axle loads on a vehicle. They are usually calibrated at regular intervals to ensure accuracy. The most common way to do this is by using the axle weighing pad calibration check method.

- The first step is to find a flat surface that can be used as a reference for the calibration check.

- The next step is to place the axle weighing pad on the surface and then place a known mass on top of it. This known mass should be at least 2-3 times heavier than the weight of an average load so that it can compensate for any inaccuracies in measurements due to errors in calibration or measurement errors. It should also be placed symmetrically over the pad’s surface so that both sides of the axle weigh equally.

This procedure can be dangerous if not done correctly because it could lead to an underweighted or overweighted vehicle. It is important for companies who do this type of work to have a certified professional performing it. You want to ensure that your truck is safe and roadworthy. This is the point of having axle weighing pads in the first place.

Where to Buy New Weigh Pads

If you are in the market for axle weighing pads or means of measuring the weight of a load, Micro Weighing Solutions is here to help. We offer some of the most sophisticated weighing systems on the market today. Our engineers and customer services representatives are standing by to answer all of your questions. Call now or speak to one of our specialists online.

FAQs

Is MWS accredited for calibration work?

MWS operates with ISO 9001 and ISO/IEC 17025 traceability in its calibration services, showing adherence to recognised quality and technical standards.

Are calibration certificates provided?

Yes — after calibration, documentation is issued confirming calibration to the appropriate standard, which is useful for audits and compliance purposes.

Our UKAS ISO 17025 certificates show the uncertainty budgets required by the VCA.

How long does calibration take?

Turnaround times can vary. MWS aims for efficient processing to minimise downtime, but exact times depend on workload and the condition of the pads. Contact MWS for current estimates.

What are the benefits of having calibrated weigh pads?

Calibrated pads help ensure vehicles aren’t overloaded, maintain compliance with regulations, reduce safety risks, and provide confidence in weight data used for logistics or tax purposes.

Do I need to send my pads to you?

Yes — the calibration service is typically performed at the MWS facility (e.g., Leicester), where the specialised test rigs are located.

What is involved in the calibration process?

Pads are placed on MWS’s test rig and loaded up to 10 tonnes of force using a certified load cell kit. Measurements are compared against known standards and adjusted as needed to ensure accurate output.

Can I calibrate weigh pads myself?

DIY calibration is not advised. Accurately calibrating heavy axle weigh pads requires specialist equipment and trained personnel to ensure safe and precise results — something MWS technicians are equipped for.

What standards are used for calibration?

MWS calibrates weighing pads using force rigs tested with a certified reference load cell kit with ISO 17025 certification, and processes to ISO 9001 standards.

How often should axle weigh pads be calibrated?

It’s industry best practice to have weighing devices calibrated at least annually. Frequent use, environmental conditions, or inconsistent results may require more regular checks.

Why do I need my weigh pads calibrated?

Regular calibration ensures the pads remain accurate and reliable. This helps prevent overloaded vehicles, supports compliance with legal weight limits, and protects your business from fines or safety risks.

What is axle weighing pad calibration?

Axle weighing pad calibration is a precision service that tests and adjusts portable axle weighing pads so they provide accurate weight measurements when used on vehicles. MWS uses specialised rigs to apply known loads and verify pad readings to recognised standards.

Enquire about weigh pad calibration. We will respond shortly

"*" indicates required fields