A Guide to Load Cell Calibration and Maintenance

Like any precision instrument, load cells require proper care and attention to ensure accurate and reliable measurements time and again. Regular calibration and preventative maintenance practices are important in order to safeguard your weighing operations.

This blog looks at the complexities of load cell calibration, why it’s necessary, the various methods used, and how to keep your load cells in top shape.

The importance of load cell calibration

Think of calibration as a tune-up for your load cell. Over time, things like wear and tear, temperature fluctuations, and environmental conditions can cause load cells to drift from their original specs. Calibration is the process of comparing the load cell’s output to known reference weights, and making adjustments in necessary.

Regular calibration ensures:

- Accuracy: maintain precise weight readings needed for quality control, inventory management, efficiency, and more

- Compliance: meet industry standards, regulations, and customer requirements

- Safety: prevent overloads and potential equipment damage or failure

- Cost savings: reduce the risk of product recalls, wasted materials, and unexpected downtime from bad readings

Calibration methods

There are several calibration methods for load cells:

- Deadweight calibration: this traditional method uses calibrated weights to create known forces. It offers high accuracy but can be time-consuming and requires specialist equipment

- Force transfer standard: this method compares the load cell’s output to a highly accurate reference load cell. It’s more efficient than deadweight calibration and works with field calibrations

- Electronic calibration: this method simulates weight application using electronic excitation and calibration resistors. It’s a convenient and cost-effective option for less critical applications

Factors that affect load cell performance

Understanding these factors is important in order to maintain accuracy:

- Temperature: big variations in temperature can cause sensitivity shifts and affect load cell output

- Humidity: high humidity can lead to corrosion and electrical signal interference

- Mechanical loading: shock loads, vibration, or improper mounting can impact strain gauge readings and result in failure

- Electrical noise: electromagnetic interference can distort output signals

Practical maintenance tips

- Cleaning: regularly remove dust, debris, and moisture build-up from the load cell and mounting areas to prevent corrosion

- Inspection: visually check for signs of damage such as cracks, dents, or loose connections

- Troubleshooting: look for common issues like zero drift, non-linearity, or inconsistent readings to determine the need for calibration or repair

- Protection: use appropriate enclosures or covers for load cells operating in harsh environments

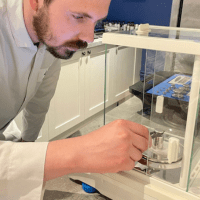

Working with a load cell partner

MWS has a dedicated team of service engineers who are skilled in the calibration and maintenance of load cells and other weighing equipment. As part of the MWS service, we will advise clients on the safest and best practices for calibration of load cells on storage silos, mixing tanks, hoppers and vessels. We are also able to provide support to clients wishing to install or replace load cells and weighing technology on existing equipment.

Contact us today to get a free quote for your calibration requirements.