Industrial Scales

for the Brewing, Distilling & Soft Drinks Industry

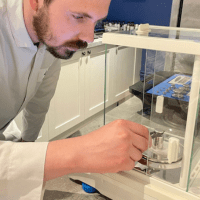

Within beverage manufacturing plants you will find an array of weighing equipment, from simple laboratory balances for measuring finite ingredients to large process weighing systems that allow businesses to blend and mix raw materials into a final product.

ATEX Scales for Drinks Manufacturers

MWS supplies distilleries across the world with ATEX weighing products designed for use where there is a risk of explosion due to flammable gasses given off in the manufacturing process and storage areas. We have worked with some of the finest whisky manufacturers in Ireland and Scotland to measure the angel’s share while spirits are stored away for many years in casks.

In breweries where there is often an abundance of water, supplying weighing equipment that stand the rigours of everyday brewing is critical. MWS has been involved in working with this niche industry for a number of years.

Providing load cells and mounts is an easy task, however, it is vital to understand some principles of weighing. This includes understanding how vessels and tanks deflect underload and avoiding interference from external factors such as pipes, which are often clamped tight onto tanks without flexible joints to allow free movement.

The range of MWS process weighing solutions provides IP rated load cells linked to process controls and load cell amplifiers connecting into complex batching systems.

We also supply a range of “end of line” product inspection solutions such as checkweighers and conveyor scales to check target weights, as well as x-ray devices to monitor fill levels in bottles.

At MWS we offer a full range of solutions for food and beverage manufacturers, from a main gate weighbridge for weighing bulk loads through to end of line automatic checkweighers and metal detectors manufactured by our partners in Italy.

Process Weighing Solutions

MWS also supplies partners involved in the development of process equipment that require an element of weighing. We can provide integration into systems that use PLCs for control such as batch weighers.

We have the knowledge and experience to ensure projects featuring load cells are done right the first time. For enquiries please contact the office on 0845 260 2602, email at sales@mws.ltd.uk or chat with us online.