CASE STUDY

CASE STUDY

Revolutionising Vehicle Weighing for a Leading Multi-Drop Parcel Delivery Company

A multi-drop parcel delivery company was looking to implement a fully automated solution for weighing vehicles before going on the road.

CUSTOMER PROFILE

In 2022, Micro Weighing Solutions (MWS) was approached by one of Europe’s largest multi-drop parcel delivery companies, operating multiple sites across the United Kingdom. This client was looking for an automated solution for weighing vehicles before embarking on their delivery routes.

THE CHALLENGE

The client had been using portable weighpads at each of their sites, which required constant relocation and manual monitoring of vehicles. This cumbersome process limited their ability to conduct thorough weight checks, leading to spot checks rather than comprehensive ongoing assessments.

The client’s primary objective was to transition from a temporary, reactive weighing system to a permanent, automated solution.

THE SOLUTION

The solution required by the client does not currently exist in the market. As such, MWS and the client worked collaboratively to devise a groundbreaking product that stands alone as a unique innovation in the market of vehicle weighing.

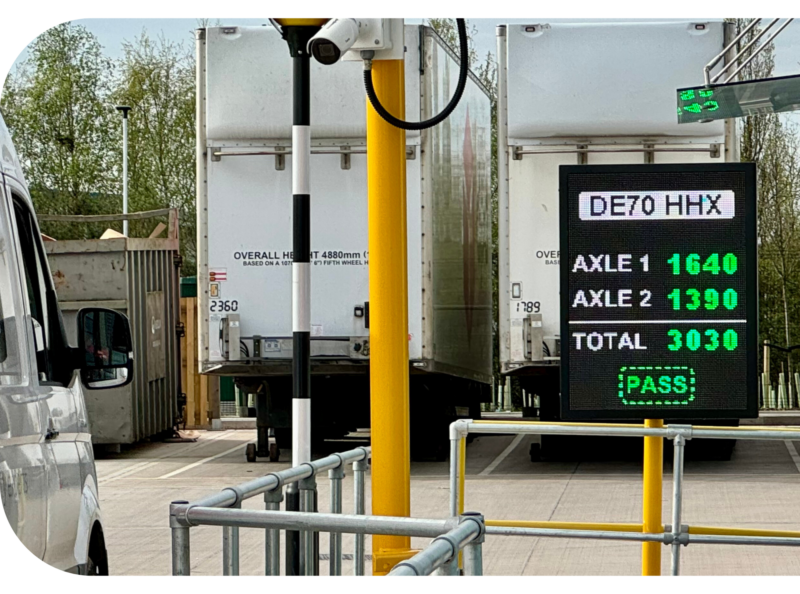

Central to this solution is the MWS axle weigher, onto which the vehicle travels over in one fluid movement. An Automatic Number Plate Recognition (ANPR) system reads the registration plate and instantly cross-references the vehicle’s weight with a comprehensive database of vehicle classifications.

Once the weighing process has been completed, the system provides real-time feedback to the driver, indicating whether the vehicle is within weight limits or if the gross axle weight exceeds the permitted threshold.

This information is displayed on a large VMS screen positioned in front of the vehicle, with the entire process taking just 6 seconds from the time the driver arrives at the weigh station.

Integral to this revolutionary system is MWS’s cloud-based management software, which operates seamlessly on 4G and 5G networks. This web application efficiently collects data from various sites and consolidates it into a centralised database, providing the client with a holistic view of diverse datasets using third party reporting tools such as Power BI and Google BigQuery.

RESULTS

CONCLUSION

The introduction of this automated solution has yielded a multitude of benefits. Most notably, it has significantly reduced the chance of overloaded vehicles on the public highways. This, in turn, has improved vehicle durability and enhanced road safety. Furthermore, the system ensures compliance with relevant vehicle weight regulations, elevating the client’s operational integrity.

Beyond these advantages, the automated system has also eliminated the manual labour associated with the use of portable weighpads and has sped up the process of getting compliant vehicles on the road.

As a result, the client is currently in the process of implementing this revolutionary system across all their depots throughout the UK, underscoring the transformative impact of the collaboration between MWS and the client.