Industrial Weighing Scales

for the Meat, Fish & Dairy Industry

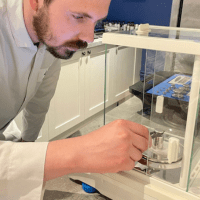

At MWS we have been manufacturing and supplying weighing equipment, traceability software and support to Meat, Fish and Dairy processors for a number of years.

Our comprehensive range of weighing equipment and software can be used across the entire production and processing sites from goods-in through to despatch. We provide solutions for all types of process and monitoring along the journey through the factory.

End-to-End Weighing Solutions

At MWS we have a full range of solutions, from pilot plant projects through to large scale process weighing systems and end of line automatic checkweighers and metal detectors manufactured by partners in Italy.

MWS’ flagship software solution “WeighLogic” is currently being used by some well know household manufacturers to manage goods-in, stock control, recipe weighing, labelling, waste traceability, batch yields and goods-out.

Stand alone solutions include small portion control weighing scales through to large platform scales and tote bin weighers, all designed and manufactured at the factory in Leicester.

End of line inspection products include Automatic High Speed Checkweighers, Metal Detectors, Combination Checkweighers and X-Ray Contamination systems to ensure product quality.

Process Weighing Solutions

MWS also supplies partners involved in the development of process equipment that require an element of weighing. We offer integration into systems that use PLCs for control such as batch weighers, for example.

At MWS we have the knowledge and experience to ensure projects featuring load cells are done right the first time.

If you have any questions about what solution is right for you, please get in touch and a member of our team would be happy to help.

Food Scales FAQ

What scales are used in the food industry?

The food industry uses a range of hygienic weighing scales designed to operate safely in wet, washdown, and regulated environments. Common types include bench scales, floor scales, platform scales, checkweighers, and portion control scales.

For food production, these scales are typically manufactured from 304 or 316 stainless steel, feature sealed load cells, and have smooth, easy-to-clean surfaces to reduce the risk of contamination. Scales used in food environments are often rated IP67 or higher to withstand regular washdown and exposure to cleaning chemicals.

Choosing the right food industry scale depends on the application, required accuracy, hygiene standards, and cleaning regime, but durability, washdown protection, and serviceability are always key considerations.

How much do hygienic scales cost?

Hygienically designed scales range in cost depending on a number of factors including the materials used, function, size and capacity. Properly-designed hygienic scales are rarely the cheapest option on day one, but they are built to withstand harsh cleaning regimes and daily use without degrading, saving you money and downtime in the long run.

What IP rating should I look for (IP65, IP67, IP68)?

The correct IP rating for weighing scales depends on how wet the environment is and how the scale will be cleaned:

- IP65 scales are suitable for dry areas and light cleaning (splash resistance).

- IP67 scales are ideal for food production and washdown environments, offering strong protection against water ingress during regular cleaning.

- IP68 scales are designed for full immersion and are rarely required in food factories.

For most food and washdown applications, IP67 is the recommended IP rating for long-term reliability.

Are load cells protected against moisture and corrosion?

Yes. In food and washdown environments, load cell protection is critical. MWS scales use sealed load cells designed to resist moisture ingress, corrosion, and cleaning chemicals.

Poorly protected load cells are one of the most common causes of scale failure in wet production areas. A hygienic design with sealed components helps improve reliability and reduce downtime.

What materials are best for weighing equipment in food environments?

For food environments, 304 or 316L grade stainless steel is widely regarded as the right choice. These grades are more resistant to corrosion and better suited to regular exposure to water, chemicals, and cleaning agents. A glass bead blast finish is also worth looking for, as it creates a smooth, uniform surface that is easier to clean and less likely to trap residue.

Do small components really make a difference to hygiene?

Yes – small details matter. Fasteners are a good example. Even standard stainless steel bolts can rust over time when exposed repeatedly to cleaning chemicals. Once corrosion sets in, removing fasteners for servicing or repair can become difficult and time-consuming.

High-quality hygienic designs carefully select materials, finishes, and components that are better suited to washdown environments and easier to work with throughout the life of the scale.

Why does hygienic design matter beyond visible surfaces?

Hygienic design is often about what you cannot see. Scales built with fully welded and capped box section frames avoid gaps, joints, and open ends where moisture and product can collect.

These hidden crevices are a common place for bacteria to harbour, particularly in busy production environments where cleaning time is limited. A fully sealed, welded construction allows for more effective washdown and reduces the risk of contamination, helping to meet the expectations of auditors and regulators.

Are UK-manufactured scales better than imported alternatives?

While lower-cost imported equipment can be tempting, there are practical trade-offs to consider. UK-manufactured scales typically offer better build consistency and a longer working life, especially in demanding food environments.

Support is also an important factor. If a component fails or servicing is required, sourcing parts locally is usually faster and more reliable. Long lead times or discontinued components can quickly outweigh any initial cost savings.

How long is the expected service life of an MWS scale?

MWS scales are built for long-term use in demanding food environments. MWS-manufactured scales come with a lifetime guarantee on the structural integrity of the scale, reflecting the strength of the welded stainless steel construction.

Key components such as load cells are covered by a 5-year warranty. With regular servicing and calibration, an MWS scale is designed to deliver reliable performance over many years in washdown environments.

Is it important to service and calibrate a food scale?

Regular servicing and calibration are essential for maintaining accuracy and compliance. A well-designed scale should be straightforward to calibrate and service, without the need for specialist tools or proprietary software.

It is also worth checking that you are not locked into a single supplier for calibration or maintenance. Flexibility here can reduce costs and make routine upkeep far less disruptive to operations.

How often should food weighing equipment be calibrated?

Food weighing equipment should typically be calibrated at least once per year to maintain accuracy and support compliance requirements.

More frequent calibration may be recommended if the scale is used heavily, exposed to regular washdowns, or used for critical production checks. Routine calibration ensures accurate weighing, reduces risk, and supports audit standards.

Do you offer custom-designed weighing solutions?

Yes. Custom design is one of MWS’s core strengths. Our in-house manufacturing facility in Leicester allows us to create bespoke weighing solutions tailored to your exact requirements.

Custom Capabilities:

Tailored Dimensions:

- Non-standard platform sizes to fit your space

- Custom heights for loading requirements

- Specialized shapes for unique products

Application-Specific Design:

- Integration with existing production lines

- Hygienic designs for food and pharmaceutical environments

- Extreme environment solutions (temperature, corrosion, hazardous areas)

- Multi-scale systems with centralized control

Industry Solutions:

- Vehicle weighing systems for unique site configurations

- Overhead weighing for meat and fish processing

- Silo and tank weighing with custom mounting

- Conveyor integration for production lines

- Recipe formulation systems with multiple scales

Software Integration:

- Custom data management solutions

- Integration with your ERP or WMS systems

- Automated batching and process control

- Traceability and reporting systems