Understanding “Traceable to National Standards”

In the world of measurement and calibration, you’ll often hear the phrase “traceable to national standards.” But what does this seemingly technical term actually mean, and why is it so important? In essence, it’s about ensuring the reliability and comparability of your measurements by linking them to the highest possible authority – the national measurement standards.

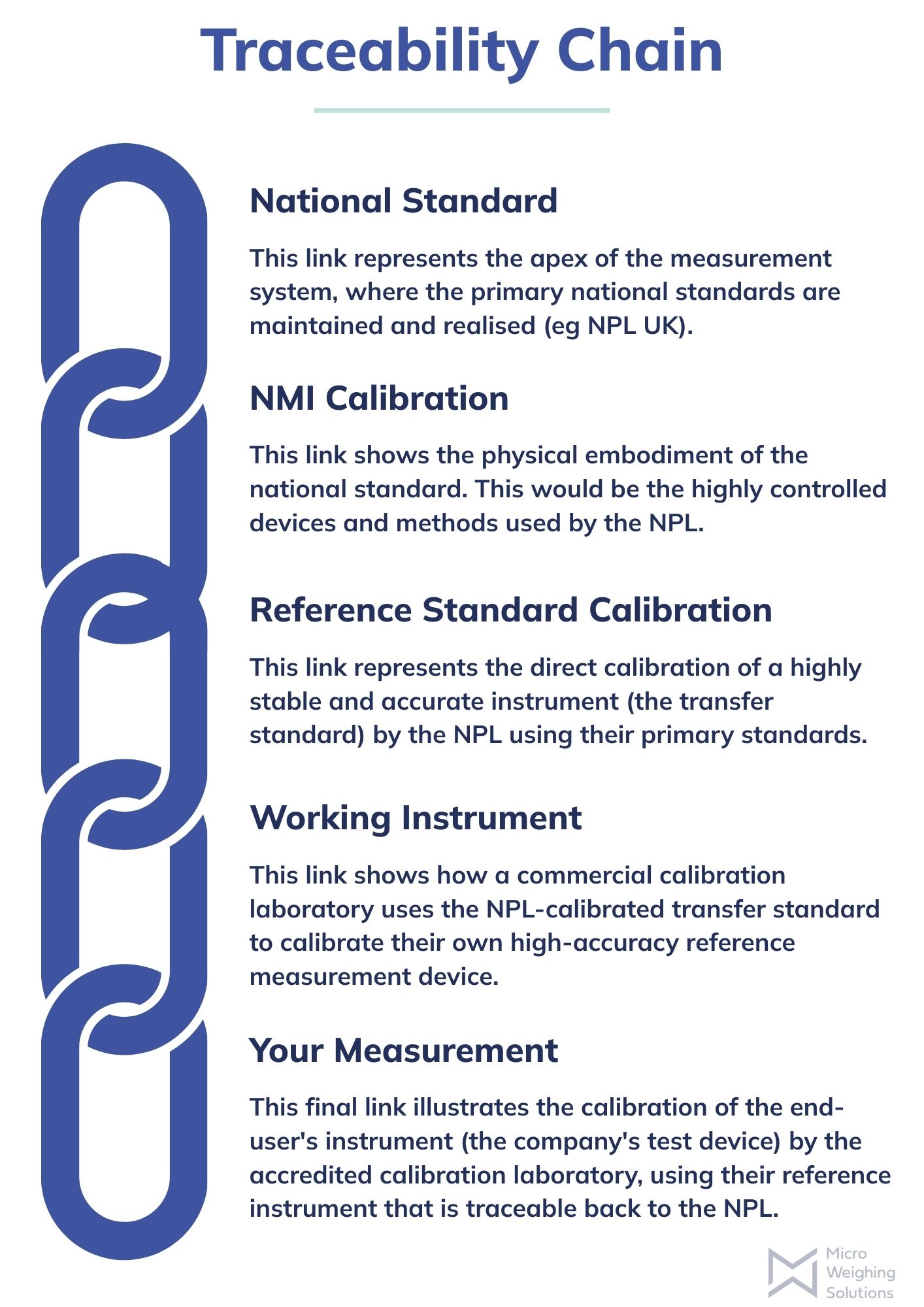

Think of it like a family tree for your measurements. At the very top sits the National Measurement Institute (NMI) of a country, like the National Physical Laboratory (NPL) here in the UK. The NPL maintains the primary standards for all sorts of measurements – length, mass, time, temperature, etc. These standards are the ultimate reference points, meticulously defined and maintained.

What does it mean for your equipment to be traceable to these standards?

It means that the calibration of your measuring instrument has been performed through an unbroken chain of comparisons, each with a documented uncertainty, ultimately leading back to the NPL’s primary standard. There are no gaps in this chain, and the accuracy at each step is carefully controlled and recorded.

Let’s look at a practical example:

Imagine a food manufacturing company in the UK needs to ensure their ovens are at the correct temperature for food safety. They use a thermometer for quality control. To ensure their measurements are reliable and can be trusted by auditors and consumers, they need their thermometer to be traceable to national standards. Here’s how that traceability might look:

- The company sends its thermometer to a calibration laboratory. This isn’t just any lab; it’s one that understands the importance of traceability.

- This calibration laboratory has its own highly accurate “reference thermometer.” This reference thermometer has been recently calibrated against an even more precise “transfer standard” thermometer. The calibration certificate for this reference thermometer clearly states its accuracy and its calibration source.

- Crucially, this “transfer standard” thermometer was calibrated directly by the National Physical Laboratory (NPL). The NPL, as we know, maintains the UK’s primary temperature standards, based on the internationally agreed International Temperature Scale of 1990 (ITS-90). They meticulously realise the defining fixed points of this scale using high-purity materials and precise techniques.

Therefore, when the calibration laboratory calibrates the food company’s thermometer against their traceable reference thermometer, the measurement of the food company’s thermometer becomes indirectly linked back to the NPL’s primary temperature standard. The calibration certificate provided to the food company will state this traceability, providing confidence in the accuracy of their temperature measurements.

Why is this important?

- Accuracy and Reliability: Traceability provides confidence that your measurements are accurate and reliable, as they are linked to a trusted source.

- Comparability: Measurements made with instruments traceable to the same national standards are comparable, regardless of where they are taken. This is crucial for trade, industry, and scientific research.

- Regulatory Compliance: Many industries and regulations require measurements to be traceable to national standards to ensure product quality, safety, and fair trade.

- Reduced Risk: Using traceable measurements helps reduce the risk of errors and inconsistencies, leading to better decision-making and fewer costly mistakes.

As you can see, “traceable to national standards” is more than just a technical phrase. It’s the invisible chain that connects your measurements to the fundamental units defined by the nation’s experts, ensuring accuracy, reliability, and trust in the data you collect. Understanding this concept is vital for anyone who relies on precise and dependable measurements in their work.

Speak to MWS today if you would like a quote to calibrate your test and measurement devices to national standards.