Analytical Balance or Top Loader? A Straightforward Buyer’s Guide

Choosing a weighing balance can feel more complicated than it needs to be. On paper, the differences look technical. In practice, it usually comes down to how much accuracy your work genuinely requires and how much day-to-day fuss you’re willing to deal with.

This guide walks you through the essentials so you can decide with confidence.

Starting with the basics

Every balance is built around one simple question: how small a change do you need to measure?

Analytical balances handle very tiny changes. Top loaders deal with slightly larger ones. Both are reliable, but they serve different jobs.

When an analytical balance makes sense

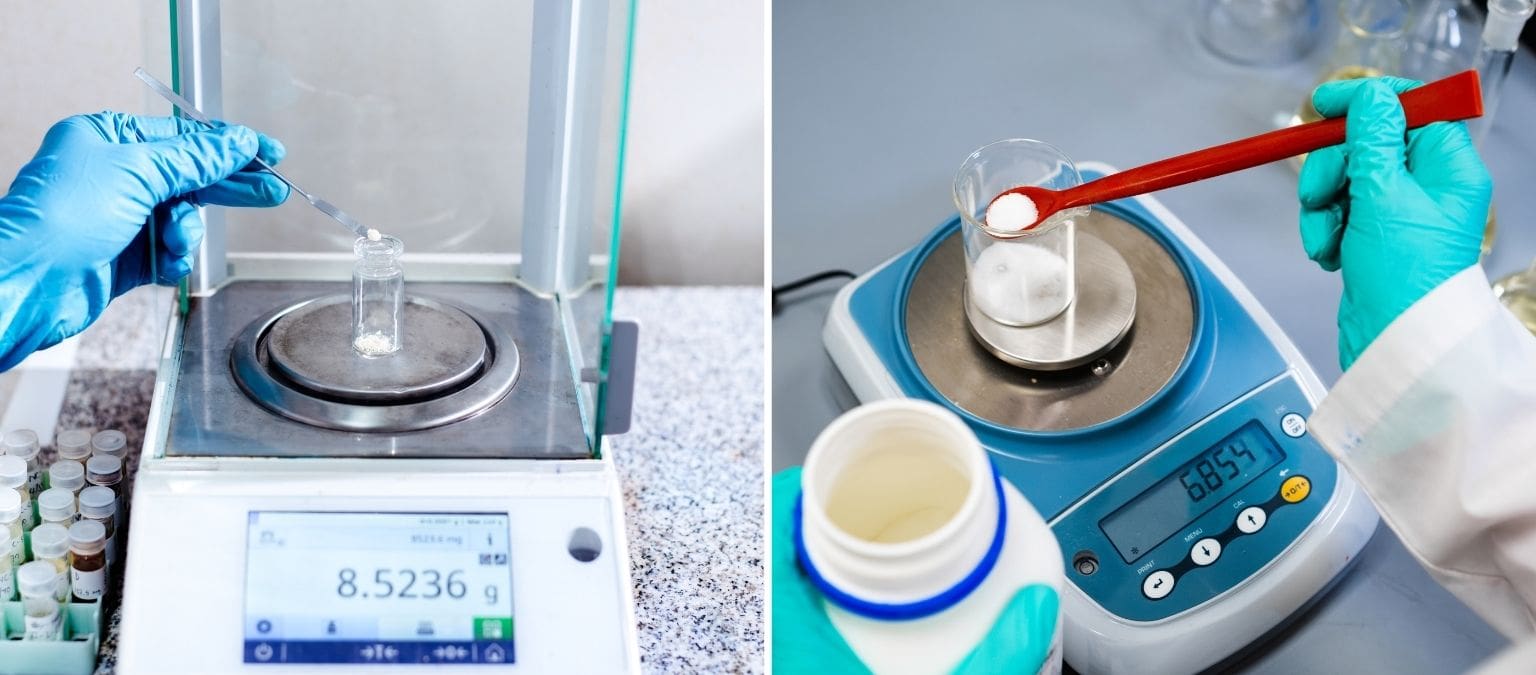

Analytical balances measure down to 0.0001 g. That level of precision is ideal for tasks where even a tiny deviation matters, such as chemical analysis, formulation work or anything that feeds into strict quality systems.

Because these balances pick up the slightest disturbance, they sit inside a draft shield. This keeps out air movement, helping the readings stay stable. If your work involves powders, solvents, reagents or anything where accuracy is non-negotiable, an analytical balance is usually the right tool.

In short: choose this if absolute precision is central to your process.

When a top loader does the job

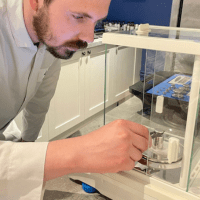

Top loader balances are far more relaxed. Their readability usually sits between 0.001 g and 0.1 g. They are sometimes called semi-analytical, but that simply means they’re designed for everyday weighing where extreme precision is unnecessary.

They load from above, they’re quick to use and they rarely come with a weighing chamber. This makes them handy in production areas, food environments, education labs and general manufacturing. They cost less than analytical balances and stand up well to regular handling.

If your work involves batching, portioning, routine checks or anything with a bit of tolerance built in, a top loader will feel like a practical choice.

Still unsure?

Here are a few quick questions to help you:

- Would a tiny variation change the outcome of your work? If yes, lean toward analytical.

- Do you need results fast and with minimal setup? A top loader keeps things simple.

- Will the balance live in a busy environment with people moving around? A top loader copes better.

- Are you working under tight regulatory controls? Analytical balances offer the traceability you may need.

- Sometimes the best option becomes obvious once you match the tool to the environment rather than the specification sheet.

A final thought

Both balance types earn their keep when used for the right job. The key is being honest about the level of accuracy you truly need and the conditions you’ll be working in. Precision is valuable, but practicality matters just as much.

It’s also important to remember that you will need to ensure your balance is regularly calibrated, regardless of which type of balance you choose. Otherwise, your results will become inaccurate.

If you’d like help choosing a model that fits your process, MWS can talk you through the options and set you up with something that will serve you well. Get in touch today for a free consultation from one of our lab weighing specialists.