Load Cells

At Micro Weighing Solutions, we take the time to understand what you actually need from Load Cells. With decades of combined experience installing load cells across every kind of industry, we know what works, and we’re here to share that knowledge with you.

Choosing the right load cell can feel overwhelming with all the options out there. That’s where we come in. We’ll walk you through the selection process, explain the pros and cons of each option, and help you make a decision you can feel good about. Because we’re not tied to any single brand, we can recommend whatever genuinely fits your application best, not just what’s easiest for us to sell.

When you work with Micro Weighing Solutions, you’re getting honest advice backed by real experience and access to our full network of trusted suppliers.

| Popular Load Cell Types | |

Shearbeam Load CellShear beam load cells are versatile and accurate, commonly used in platform scales, conveyor systems, and medium-capacity weighing applications. Their low profile design makes them easy to integrate into tight spaces, and they handle off-center loading well while maintaining precision. We’ll help you determine if a shear beam load cell is the right choice based on your platform size, capacity needs, and installation constraints. |

|

Compression Load CellCompression load cells are built to handle forces pushing down on them, making them ideal for applications like tank weighing, platform scales, and heavy industrial machinery. They’re straightforward, reliable, and can take a beating in tough environments. |

|

Tension Load CellsTension load cells measure pulling or hanging forces, perfect for crane scales, hoppers, and suspended tank systems. They excel when you need to weigh something hanging rather than sitting on a platform. We’ll walk you through whether a tension load cell suits your application based on your load capacity and mounting arrangement. |

|

Single Point Load CellsSingle point load cells are designed for smaller platform scales where the load doesn’t need to be perfectly centered. They’re commonly used in bench scales, retail scales, and checkweighers because they deliver accurate readings regardless of where the weight sits on the platform. We’ll help you determine if a single point load cell fits your needs based on your platform size and accuracy requirements. |

|

Silo Load Cells / Bulk Tank Load CellsSilo and bulk tank load cells are built for heavy-duty weighing in industrial storage applications. They handle high capacities while dealing with side loads, vibrations, and harsh environmental conditions that come with silos, hoppers, and large storage tanks. We’ll help you select the right load cells based on your tank configuration, capacity requirements, and site conditions. |

|

Weighbridge LoadcellsWeighbridge load cells are engineered for high-capacity vehicle weighing and built to withstand constant heavy loads and environmental exposure. Whether you’re updating an aging weighbridge system or repairing a failed load cell, we can help you get back up and running quickly. We’ll assess your existing setup, recommend the right replacement or upgrade, and ensure your weighbridge delivers accurate, reliable readings for years to come. |

|

Our Load Cell Brands

At Micro Weighing Solutions, we work with industry-leading load cell manufacturers to ensure you get the right solution for your application. Our partnerships with brands like Flintec, Dini Argeo, and Rice Lake mean we can handle virtually any weighing challenge you throw at us.

Flintec is one of the most trusted names in load cell technology, offering an extensive range that covers everything from precision laboratory scales to heavy industrial weighing systems. Their products are known for reliability and accuracy across the board. Whether you need single point load cells for bench scales or high-capacity compression cells for bulk weighing, Flintec has proven solutions that perform in real-world conditions.

Dini Argeo brings Italian engineering excellence to the weighing industry. They specialize in complete weighing systems and load cells designed for industrial environments, particularly excelling in applications like platform scales, tank weighing, and process control systems. Their products are built tough for demanding applications where downtime isn’t an option.

RiceLake is a comprehensive weighing solutions provider with a product range that spans from small retail scales to massive truck scales and everything in between. Their load cells are engineered for longevity and backed by exceptional technical support. Rice Lake’s variety means we can match you with the exact specifications your application demands.

We also supply quality load cells from Zemic, HBK (formerly Hottinger Baldwin Messtechnik), Vishay, and Thamesside, each bringing their own strengths to specific applications and industries.

The beauty of working with MWS is that we’re not locked into a single brand. We assess your actual requirements and recommend the manufacturer and model that genuinely fits best. Sometimes that’s a premium solution, sometimes it’s a cost-effective workhorse. Either way, you’re getting honest advice based on what will actually work for your situation, backed by our decades of installation experience.

Why Choose Micro Weighing Solutions

Whether you’re an end user integrating load cells into your production line or a manufacturer building weighing systems into the products you sell, Micro Weighing Solutions gives you the expertise and flexibility you need to get it right.

We understand that every weighing application is different. A food processing plant replacing load cells on their mixing tanks has completely different requirements than an OEM building portable weighbridges for export. That’s why we don’t push a one-size-fits-all solution. We listen first, then recommend what actually makes sense for your specific situation.

Our relationships with manufacturers like Flintec, Dini Argeo, and RiceLake give us access to load cells that cover practically every weighing scenario imaginable. From milligram-precision laboratory cells to 100-ton capacity weighbridge modules, we can source it. This breadth means you’re not settling for “close enough” because we’re limited by brand restrictions. You get what genuinely fits.

For end users, we bring practical installation knowledge that comes from doing this work across multiple industries for years. We’ve seen what works in chemical plants, quarries, ports, and manufacturing facilities. We know the questions to ask about your environment, mounting constraints, and accuracy requirements because we’ve solved these problems before.

For OEMs and system integrators, we’re set up to support your business with consistent supply, technical backing, and the flexibility to scale as your production demands change. We understand that when you’re building weighing into your products, reliability and consistent performance aren’t optional, they’re essential to your reputation.

At MWS, you’re not just buying components off a shelf. You’re getting a partner who understands weighing, knows the products inside and out, and is invested in making sure your application succeeds. That’s the difference between a supplier and a solutions provider.

Loadcell Installation: Getting It Right Matters

Even the best load cell won’t perform properly if it’s installed incorrectly. We’ve seen expensive equipment underperform or fail prematurely simply because installation fundamentals were overlooked. That’s where having experienced guidance makes all the difference.

Proper load cell installation starts with understanding how forces travel through your proposed system. Loadcells need to receive force in the direction they’re designed for, ideally without side loads or torsional stresses which affect readings or over the long term damage the sensor.

Mounting surfaces should be flat, level, and rigid enough to prevent flexing that introduces errors. Environmental factors like temperature fluctuations, moisture ingress, and vibration all need consideration during installation, not after problems emerge. We can mitigate issues with surfaces by using rubber mounts, shims or mounts that can create lateral force when applied at angles.

Cable routing matters more than most people realise, its usually a the worst element of systems we encounter in the field. Poorly protected or incorrectly routed cables can pick up electrical interference, get damaged by moving equipment, or create ground loops that cause erratic readings, not only that it looks unsightly and messy, it just doesn’t look very good. We’ve troubleshot multiple “faulty load cell” issues that turned out to be cable problems that could have been avoided with proper installation from the start.

Then there’s calibration and testing. Installing the load cell is only half the job. The system will need proper calibration with known weights or mass, and thorough testing under actual operating conditions to ensure it performs as expected when your production plant starts.

At Micro Weighing Solutions, we don’t just supply load cells and wish you luck.

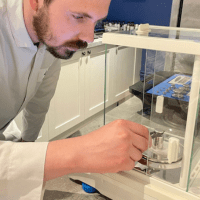

We guide you through the installation process, highlighting the critical steps specific to your application and equipment. For more complex installations or where precision is critical, we offer installation services where our service engineers handle the entire process, from mechanical mounting through to electrical connection, calibration, and final testing with traceable certification provided on our online platform.

We’ve installed load cells in everything from clean room environments to dusty quarries, from static vessel weighing to dynamic conveyor systems. That experience means we know what works, what doesn’t, and how to avoid the common mistakes that cost time and money.

When you work with MWS, you’re tapping into practical knowledge that ensures your weighing system performs reliably from day one and for many years to come.

Load Cell Calibration: Accuracy You Can Trust

A load cell is only as good as its calibration. Without proper calibration, you’re just guessing at weights, and in industries where accuracy affects product quality, compliance, or profitability, guessing isn’t good enough.

There are several calibration methods, each suited to different situations. Dead weight calibration is the gold standard. This involves applying known certified weights directly to the system and adjusting the output accordingly. It’s straightforward and accurate, but it requires having certified weights available and physical access to load the system, which isn’t always practical for large capacity installations.

Substitution calibration works well when you can’t bring certified weights to site. You load the system with material, measure it on a certified external scale, then use that known weight to calibrate your load cells. It’s common in industrial settings where moving a 10-ton hopper to a calibrated scale beats trying to source 10 tons of certified weights.

For very high capacity systems like weighbridges, incremental loading is often used. Certified weights are placed at specific points on the platform in stages, and mathematical calculations account for the full capacity based on these incremental measurements. This method requires expertise to execute properly but allows accurate calibration without needing the full capacity in test weights.

At Micro Weighing Solutions, we handle calibration as part of our installation service or as a standalone offering for existing systems. We arrive with calibrated test weights traceable to national standards, the right instrumentation, and the experience to know when readings look right and when something needs adjustment.

We document everything. You’ll receive calibration certificates showing the weights used, the readings achieved, and confirmation that your system meets the accuracy specifications you need. Whether you require annual recalibration for compliance purposes or you’re commissioning a new installation, we make sure your weighing system delivers numbers you can rely on.

Contact Us

If you’re looking for a dependable load cell calibration partner who understands your industry and equipment inside out, get in touch with the team at MWS today.

Load Cell FAQs

What is a load cell and how does it work?

A load cell is a transducer that converts mechanical force or weight into an electrical signal. When force is applied to the load cell, it causes deformation in a strain gauge element. This deformation changes the electrical resistance of the strain gauge, which is then measured and converted into a precise weight or force reading. Load cells are essential components in weighing systems, from small bench scales to large industrial applications like tank weighing and vehicle scales.

What are the main types of load cells used in industry?

The most common industrial load cell types include compression load cells (designed to measure pushing forces), tension load cells (for pulling forces), and shear beam load cells (resistant to side loads). Other specialized types include bending beam load cells for platform scales, S-type load cells for both tension and compression, canister load cells for high-capacity applications, and single point load cells commonly used in bench and floor scales. The choice depends on your specific application, capacity requirements, and environmental conditions.

How do I select the right load cell capacity for my application?

Load cell capacity should typically be rated 50-100% higher than your maximum expected load to ensure accuracy and longevity. For example, if your maximum load is 1,000 kg, choose a load cell rated for 1,500-2,000 kg. This safety margin accounts for shock loads, uneven weight distribution, and ensures the load cell operates within its optimal accuracy range. For multi-load cell systems, divide the maximum total load by the number of load cells and apply the safety factor to each cell.

What is load cell accuracy class and why does it matter?

Load cell accuracy is classified according to international standards, with common classes being C3 (3,000 divisions), C4 (4,000 divisions), and C6 (6,000 divisions). The class indicates how many increments the load cell can reliably measure within its capacity. Higher class numbers mean greater precision. C3 load cells are suitable for general industrial weighing, while C6 load cells are used for legal-for-trade applications and precision industrial processes. Your accuracy requirement should match your application’s tolerance needs and any regulatory requirements.

Can load cells operate in harsh environmental conditions?

Yes, many industrial load cells are specifically designed for challenging environments. Stainless steel load cells offer excellent corrosion resistance for wet, washdown, or chemical environments. IP68-rated load cells provide protection against dust and water ingress, making them suitable for outdoor use or food processing applications. For extreme temperatures, specialized load cells can operate from -40°C to +80°C or higher. When selecting a load cell, always consider environmental factors including moisture, temperature extremes, corrosive substances, and potential impact or vibration.

What is the difference between analog and digital load cells?

Analog load cells output a low-level millivolt signal proportional to the applied load, requiring separate signal conditioning and analog-to-digital conversion. Digital load cells have built-in electronics that convert the signal to digital format within the load cell itself, providing better noise immunity, longer cable runs without signal degradation, and easier multi-load cell installations. Digital systems also offer individual load cell diagnostics and calibration. While analog systems are typically less expensive, digital load cells provide superior performance in complex industrial applications and are increasingly becoming the standard.

How often do load cells need calibration?

Calibration frequency depends on usage intensity, accuracy requirements, and regulatory standards. For general industrial applications, annual calibration is typical. High-precision or legal-for-trade applications may require calibration every 6 months or quarterly. Load cells should also be recalibrated after installation, relocation, repairs, or if accuracy appears compromised. Regular verification checks between formal calibrations help identify drift early. Maintaining calibration records is essential for quality systems and regulatory compliance.

What causes load cell measurement errors and how can they be prevented?

Common causes of load cell errors include incorrect installation (binding, side loading, or eccentric loading), temperature fluctuations, electrical interference, mechanical shock, and moisture ingress. Prevention measures include proper mounting with load buttons or kits that accommodate thermal expansion, using appropriate cable shielding and grounding, installing surge protection, ensuring environmental seals remain intact, and regular inspection. Side loads can be minimized using check rods or anti-tilt devices. Proper installation according to manufacturer specifications is critical for long-term accuracy.

Can existing load cells be replaced or upgraded without replacing the entire system?

In most cases, yes. Load cells can be replaced with equivalent models having the same capacity, output, and mounting dimensions. When upgrading, you may need to verify compatibility between the new load cell and existing instrumentation, particularly regarding sensitivity (mV/V rating) and input/output specifications. Converting from analog to digital load cells typically requires replacing the indicator or controller as well. It’s advisable to consult with your supplier or the original equipment manufacturer to ensure compatibility and optimal performance after replacement.

What maintenance do load cells require?

Load cells require minimal but important maintenance. Regular visual inspections should check for physical damage, corrosion, loose mounting bolts, and cable integrity. Keep load cell surfaces clean and free from debris buildup that could affect accuracy. Verify that environmental seals remain intact and that no moisture has entered junction boxes. Check mounting hardware for tightness and ensure no binding has developed in the mechanical system. Perform periodic accuracy checks using calibrated test weights. Maintain records of all inspections, calibrations, and repairs. Proper maintenance extends load cell life and ensures consistent accuracy.