Scale Calibration Services

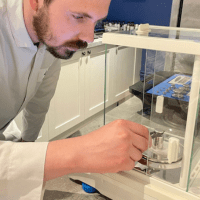

Micro Weighing Solutions is one of the only UK weighing manufacturers that provides a truly end-to-end weighing service, from design and manufacturing of scales through to installation, calibration and on-going service and maintenance.

Our service and calibration teams have decades of experience in the industry and operate out of both the Head Office in Leicester and the Northeast Service Centre located in County Durham. This means we can travel nationwide to carry out maintenance and calibration of all types of weighing products from analytical lab balances through to weighbridges and silos. We also provide a scale repair service to get your equipment back up and running.

Traceable Scale Calibration

The MWS service team visits clients’ sites to carry out routine preventative maintenance and traceable scale calibration.

MWS is ISO 17025 UKAS and ISO 9001 accredited, and also has the ability to self verify for trade approval of Class III weighing equipment. External audits and accreditation are awarded by the UK Metrology Board.

Calibration Procedures

As part of the service visit, the weighing machine is tested in an “as found” state. This provides you with the ability to monitor the performance of the asset from the last time it was adjusted.

If the weighing machine is deemed to be outside of pre-determined tolerances, then the next step is the calibration and adjustment of the weighing machine. These readings are then logged as the “definitive” results on the calibration certificate. It is important to properly calibrate your scales on a regular basis; the frequency can be recommended based on monitoring previous definitive results and as found results. Wide variations could mean increased visits are necessary to eliminate errors being left too long.

The calibration and adjustment of balances and scales can be carried out to ISO 9001 2015 standards or ISO IEC 17025 UKAS standards. We have calibrated sets of calibration weights to perform adjustments for everything from 7 place ultra-micro balances through to weighbridges.

If you require measurement uncertainty, then we recommend UKAS calibration procedures for a far more comprehensive test of the performance of your weighing scale or laboratory balance. MWS has UKAS accreditation and can arrange quotes to carry out this high level of calibration.

Calibration Certificates

All documentation of the scale calibration is created in electronic PDF format, which ensures clients can easily request or download their certificates in the event of them being misplaced.

All certificates are uploaded to the MWS online portal for easy retrieval. This includes up-to-date weight certificates, company insurance documents, health & safety policies, risk assessments and method statements. “Specific task” risk assessments are available upon request.

Reasons to choose MWS:

- ISO 9001:2015 Accredited

- ISO 17025 Accredited Laboratory

- SAFEcontractor approved

- Experienced engineers

- National coverage

- Competitively priced services

Client Benefits:

- Increased life span of weighing equipment

- Expert technical advice and support

- Fast replacement of lost certificates

- Big savings on load cells and spare parts

- Lower ongoing maintenance costs

Leicester Head Office

Located just outside Leicester on the A6/A46 Interchange, MWS’ head office has a dedicated in-house service team. Our field-based engineers are strategically located to provide optimum weighing scale services nearby to the midlands and southern regions.

Northeast Service Centre

Strategically located just outside Chester-le-Street in County Durham, our regional service centre covers the North region of England and Scotland. Our north east scale calibration team is ready to help with any weighing scale and laboratory UKAS calibrations.

Accreditations, Certifications & Memberships:

When choosing a service business to carry out the maintenance and calibration of your weighing machinery, it’s important to consider the capability of the business. Micro Weighing Solutions holds all of the relevant accreditations required to carry out traceable calibration.

Our team of service engineers consists of experienced professionals who have a strong background in the weighing industry. We also have several junior engineers and apprentices who are mentored by our senior team.

As part of our commitment to the industry, we continue to invest in a high level of training for our employees – this ensures our service engineers are constantly developing their skills which benefits our clients.

Calibration FAQs

Do you offer a system/portal to manage certificates and assets?

Yes. We offer a digital system/portal option to help customers manage:

-

Certificates and service reports in one place

-

Asset registers (equipment list, IDs, locations, serial numbers)

-

Calibration/service due dates and reminders

-

Visit history and audit-ready document retrieval

How do you ensure traceability in service records and calibrations?

We maintain traceability through a controlled, auditable process that typically includes:

-

Use of calibrated reference standards with documented traceability to recognised national/international standards

-

Unique identification for customer assets (e.g., asset ID/serial number), linked to each visit, certificate, and service record

-

Controlled procedures for measurement, uncertainty reporting (where applicable), and record retention

-

Technician/engineer job records capturing environmental conditions and test configuration where relevant

-

Certificate numbering and version control to protect the integrity of the documentation over time

Do you provide calibration certificates and service documentation?

Yes. After calibration and/or service, we provide formal documentation appropriate to the work completed. This typically includes:

-

Calibration certificates (UKAS-accredited where applicable and within scope, or non-UKAS where requested/appropriate)

-

Service reports detailing findings, actions taken, parts replaced (if any), and functional checks

-

“As found / as left” results where relevant, so you have a clear audit trail of performance before and after work

Do you offer preventative maintenance and service contracts (or one-off visits)?

Can you calibrate and repair equipment from other manufacturers?

Yes. MWS engineers support multiple models and brands and can repair and calibrate equipment beyond the original manufacturer, subject to application, condition, and calibration scope.

We cover a wide range of equipment from major manufacturers such as the following, plus many more smaller brands.

-

Mettler Toledo

- Ohaus

- Dini Argeo

-

Avery Weigh-Tronix

- Kern & Sohn

-

Sartorius

-

Minebea Intec

-

A&D Weighing (A&D Company)

-

Adam Equipment

-

Rice Lake Weighing Systems

-

Bizerba

What is the difference between calibration, verification, and adjustment?

-

Calibration: determining and reporting measurement performance (metrological values) on a calibration certificate. UKAS guidance is explicit that calibration is not verification and not adjustment.

-

Verification (legal / trade approval context): a conformity process for trade-use NAWI that can only be performed by approved/notified bodies; MWS is certified for initial verification and re-verification activities for non-automatic weighing instruments.

-

Adjustment: changing the instrument to bring it closer to nominal performance; guidance notes that adjustment can invalidate existing calibration results for that system.

How often should my weighing equipment be calibrated?

Calibration frequency should be set by risk (usage, criticality, environment, audit/regulatory requirements). In practice, most customers use annual calibration, and higher-criticality applications often use 6-monthly visits. MWS service proposals and contracts commonly reflect both 12-monthly and 6-monthly service intervals, but can be tailored to each clients requirements.

Do you provide UKAS-accredited calibration services?

Yes. Micro Weighing Solutions (MWS) is UKAS accredited to ISO/IEC 17025 (UKAS Calibration Laboratory No. 9617) and issues UKAS calibration certificates with traceability to recognised standards.

What's the difference between UKAS calibration and standard calibration?

Standard Traceable Calibration (ISO 9001):

- Traceable to national standards

- Suitable for internal quality control

- Meets most general industrial requirements

- More cost-effective option

- Certificate shows calibration results

- Adequate for non-regulated industries

UKAS Calibration (ISO/IEC 17025):

- Highest level of independent accreditation

- Required for regulated industries (pharmaceutical, healthcare, some food applications)

- Provides global recognition and acceptance

- Includes detailed measurement uncertainty analysis

- Stricter documentation and traceability requirements

- May be required by customers, auditors, or regulatory bodies

- Essential for legal metrology and trade-approved equipment

- Provides an uncertainty of measurement budget

Which do you need?

If you’re unsure, our service team can advise based on your industry, application, and any regulatory requirements you must meet. Many clients use UKAS calibration for critical scales and standard calibration for general process equipment to balance cost with compliance.

When should I calibrate my industrial scales?

Routine Schedule:

- At least annually for most industrial applications

- Every 6 months for trade-approved scales used for selling goods by weight

- Quarterly or monthly for pharmaceutical and laboratory balances with critical accuracy requirements

Immediate Calibration Needed When:

- Scales are newly installed or relocated

- After any repair or maintenance work

- Following a significant impact or damage

- If you notice weighing inconsistencies or errors

- When audits or inspections identify concerns

- Before critical production runs

Industry-Specific Requirements:

- Food manufacturing: Often requires calibration aligned with HACCP procedures

- Pharmaceutical: May require daily verification checks plus periodic formal calibration

- Trade use: Legal metrology regulations mandate regular inspection

MWS offers flexible calibration service contracts to ensure your equipment remains compliant and accurate. Our nationwide service team can work around your production schedules to minimise downtime.

Contact Us

"*" indicates required fields