What are Load Cells?

Load cells might seem like humble components, but they play a crucial role in a wide array of industries, from manufacturing to logistics. These devices, often unseen but always at work, form the backbone of weighing technology, ensuring accurate measurements in countless applications. In this blog post, we’ll delve into the basic principles of load cells, explore different types, and examine their everyday applications.

How Load Cells Work

At its core, a load cell is a transducer that converts force or weight into an electrical signal. This conversion is achieved through various mechanisms, but the underlying principle remains the same: deformation. When a force is applied to the device, it undergoes deformation, resulting in a change in electrical resistance, voltage, or frequency. This change is then measured and calibrated to accurately determine the applied force or weight.

Types of Load Cells

Load cells come in various types, each suited to specific applications and environments. Here are some common types:

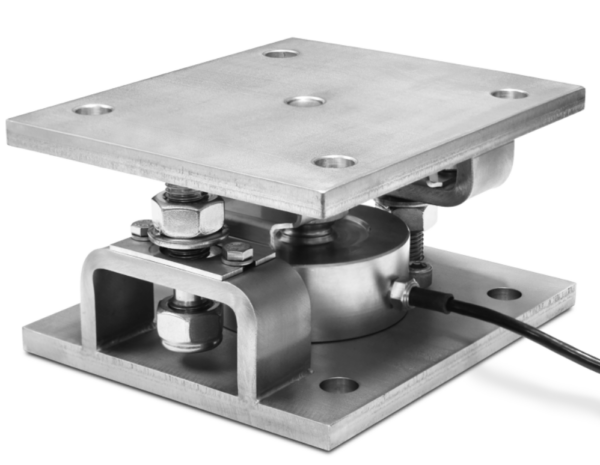

- Compression Load Cells: These load cells are designed to measure compression or pushing forces. They are often used in applications such as vehicle scales, industrial hoppers, and tank weighing systems.

- Tension Load Cells: Unlike compression load cells, tension load cells are built to measure tensile or pulling forces. They find use in crane scales, conveyor belt tension monitoring, and material testing machines.

- Shear Load Cells: Shear load cells measure the force applied parallel to the surface of the sensor. They are commonly employed in platform scales, medical devices, and aerospace applications.

- Bending Beam Load Cells: Bending beam load cells are versatile and can measure both tension and compression forces. They are widely used in retail scales, laboratory balances, and process weighing applications.

- Canister Load Cells: These load cells are highly durable and can withstand harsh environments. They are often found in hydraulic presses, truck scales, and offshore weighing systems.

How Load Cells Are Used

Load cells play a significant role in our daily lives, often working behind the scenes to ensure efficiency and accuracy. Here are some common applications:

- Weigh Bridges: Load cells are integral to the operation of weigh bridges, accurately measuring the weight of vehicles for traffic management, toll collection, and cargo handling.

- Force Gauges: Force gauges utilise load cells to measure compression or tension forces in various applications, including material testing, quality control, and product development.

- Industrial Automation: In manufacturing environments, load cells are used in automated systems to monitor and control the flow of materials, ensuring precise handling and processing.

- Medical Devices: Load cells are incorporated into medical devices such as patient scales, infusion pumps, and rehabilitation equipment to monitor and manage patient weight and force exertion.

- Retail Scales: From grocery stores to specialty shops, retail scales rely on load cells to provide accurate measurements of products, enabling fair transactions and inventory management.

From ensuring product quality to optimising processes, these devices are essential components of modern technology. By understanding the basic principles of load cells and their diverse applications, we gain a deeper appreciation for the role they play in our interconnected world.

If you’re in the market for high-quality load cells tailored to your specific needs, consider reaching out to Micro Weighing Solutions. With our expertise and commitment to innovation, we can provide personalised solutions to meet your weighing requirements. View our range of load cells and get in touch with us today to explore how our load cells can enhance the efficiency and accuracy of your operations.