- About

-

-

About MWS

-

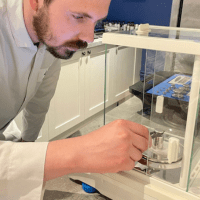

Our People

-

-

- Applications

-

-

Applications

Barcode / Pack Labelling

-

Software

-

Automation

Weigh Price Labelling

-

Vehicle Weighing

-

-

- Products

- ATEX

-

-

-

-

Premium ATEX Weighing Scale Manufacturer in the UK

MWS stands as a leading specialist in ATEX-certified weighing solutions, serving hazardous environments across the United Kingdom and beyond. With decades of expertise in explosion-proof weighing technology, MWS has established itself as the trusted partner for industries operating in potentially explosive atmospheres.

Our comprehensive range of ATEX weighing scales encompasses everything from compact bench scales to heavy-duty industrial weighbridges, all meticulously engineered to meet stringent Zone 1, Zone 2, Zone 21, and Zone 22 classifications. Every product undergoes rigorous testing and certification to ensure absolute compliance with ATEX Directive 2014/34/EU, guaranteeing safe operation in environments involving flammable gases, vapors, mists, or combustible dusts.

What distinguishes MWS is our commitment to combining safety with precision. Our ATEX scales deliver exceptional accuracy without compromising on the robust protection required in petrochemical plants, pharmaceutical facilities, chemical manufacturing sites, grain handling operations, and powder processing environments.

We provide complete turnkey solutions including expert consultation, custom design, professional installation, certification support, and comprehensive after-sales service. Our technical team possesses in-depth knowledge of both weighing technology and hazardous area regulations, ensuring seamless integration into your operations.

MWS doesn’t just supply equipment, we deliver peace of mind. When safety and accuracy are non-negotiable, industries throughout the UK choose MWS as their premium ATEX weighing scale manufacturer.

-

-

- Calibration Services

-

-

Comprehensive Calibration Services

Our range of services cover all types of

weighing equipment and site assets such as humidity, temperature & pressure gauges.

We are accredited to perform calibrations

of weighing scales and laboratory balances

ISO 9001 Traceable Calibration

We provide standard traceable calibration, we are accredited by the UK Metrology Board.

We provide prompt and reliable weighing scale repair services across the UK

-

-

Weighing Equipment

-

Site & Process Assets

-

-

- Contact

- News

- Request a Quote